Tailor-made vascular stents with 3D printing

- MIRAI 3D

- 16 abr 2021

- 2 Min. de lectura

Dr. Mariano Ferreira

Hospital Alemán - Buenos Aires, Argentina

Benefits

✔ Increased understanding of the anatomy

✔ Surgical plan design and optimisation

✔ Customised prosthesis fabrication

✔ Reduction of surgical times

Clinical case

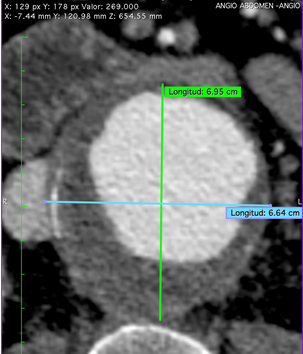

A 64-year-old male patient with a juxtarenal aneurysm almost 70 mm in diameter and a diseased infrarenal aortic segment.

The area to be stented started from a few milimeters above the superior mesenteric to a few mm below the renal arteries. For this reason, an special endovascular prosthesis compatible with this segment of the aorta had to be placed.

In general, there are two current options for creating a custom-made endoprosthesis:

Industrial fabrication, which is expensive and can take 3-4 months, a time that is often not compatible with this type of patient.

Manual fabrication, which is faster but more dependent on the surgeon's skill, in which doctors take the corresponding distances for each visceral artery with respect to the place where the prosthesis is to be placed and based on these measurements create the prosthesis.

Dr. Ferreira, in charge of the case, decided to use a third option, which is highly feasible with current technologies, which consists of using 3D models as a guide to manufacture a customised endovascular prosthesis.

3D anatomical model

◾ Technology: SLA

◾ Material: Rigid resin

◾ Resolution: 0.01 mm

◾ Finish: Translucent

Fabrication of the stent

The process of creating the patient's custom stent consisted of the following steps:

3D reconstruction of the visceral segment of the aorta was performed from the patient's CT images.

Digitally, the visceral arteries were removed, leaving a hole in the areas where they connect to the aorta.

The rigid model of the reconstructed segment was printed in high resolution.

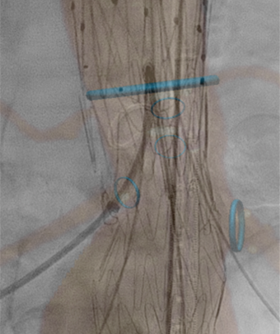

The stent was inserted into the 3D model.

Once placed in the correct position, the prosthesis was opened to copy the shape and the orifices of the arterial branches were marked on it.

The fenestrations constructed according to the anatomy obtained from the model were made, sewn and finally the prosthesis was re-sheathed.

Want to know more? You can watch Dr. Mariano Ferreira's lecture on 3D printing in vascular surgery here: Innovation in vascular surgery

Results in operating room

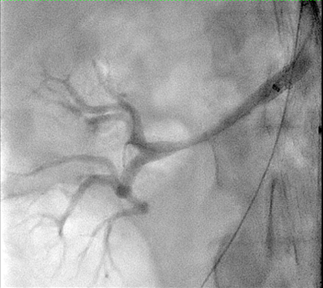

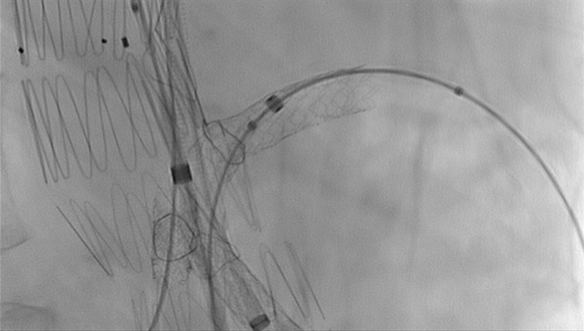

Once the custom-made prosthesis was created, it was placed using haemodynamics, preserving the superior mesenteric and right and left renal arteries. Stents were then placed in each of the outlets of the aforementioned arteries.

Through the use of 3D printing, the patient received a rapid response to treat his pathology and was successfully intervened in a fast, effective and accurate procedure.

"Very good, both academically and in terms of care", says Dr Mariano Ferreira about his experience using 3D models to create customised endovascular prostheses.